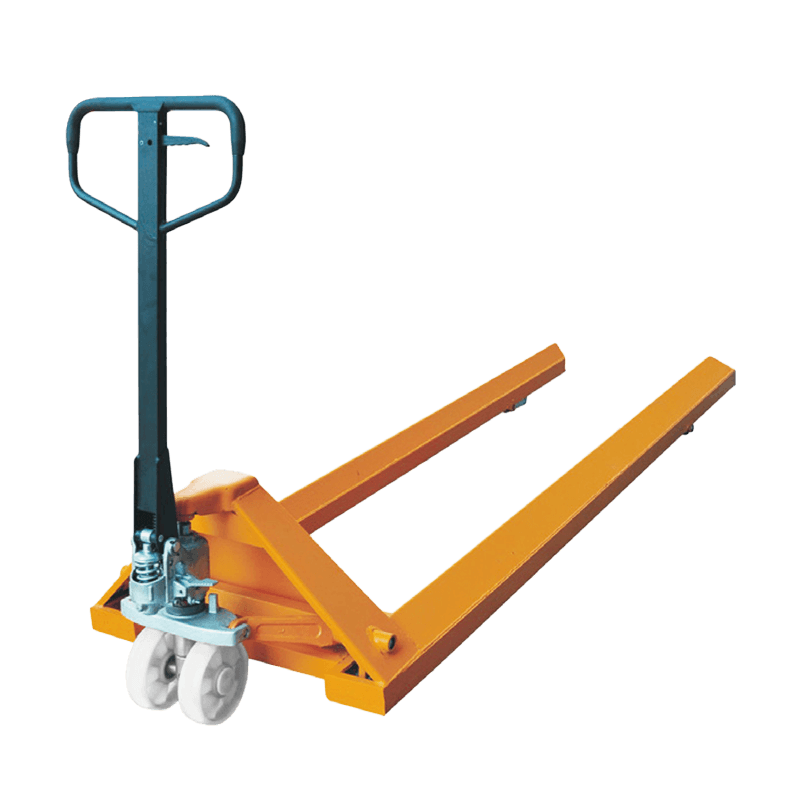

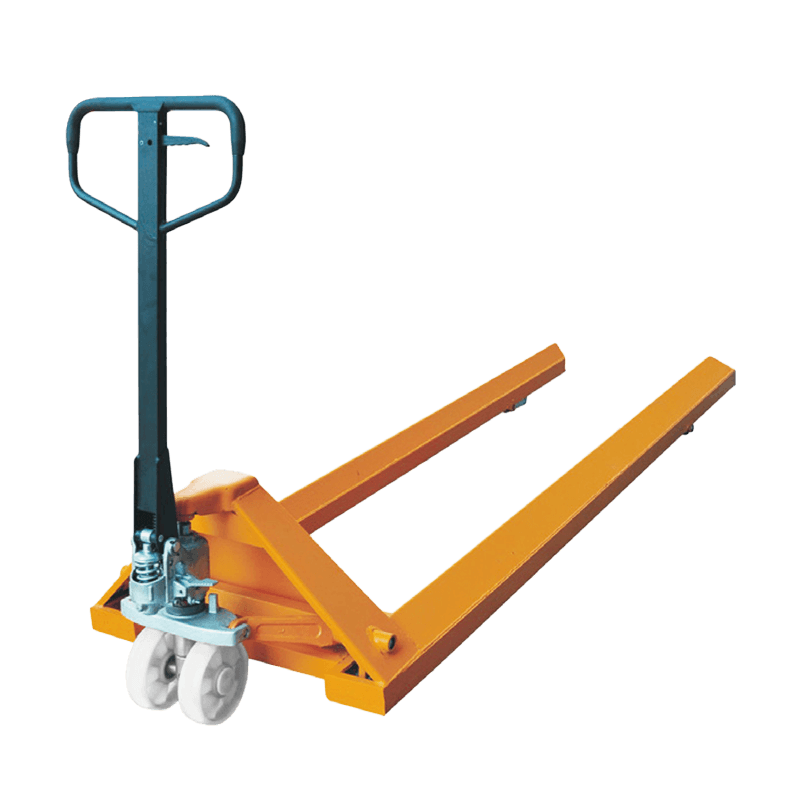

Summary:Due to the wide use of pallet truck, there are more and more points to pay attention to. We may consider his usage and how to protect them. Today, we ...

Due to the wide use of pallet truck, there are more and more points to pay attention to. We may consider his usage and how to protect them. Today, we will tell you about the corrosion of pallet truck. What are we good for? method?

1. Consider choosing corrosion-resistant materials with excellent performance, such as galvanized sheet, color-coated sheet, composite materials, engineering plastics, etc.

2. Pay attention to the protection of exposed parts. Electrical components and connectors are placed on the inside, or a protective cover enclosure is added. The exposed parts of the vehicle that are prone to corrosion and water should be provided with a dust cover. For example, the exposed parts of the tipping hydraulic cylinder and the steering hydraulic cylinder piston rod are provided with dust jackets; many exposed process holes or functional holes on the body have waterproof plugs.

3. Consider the overall arrangement to prevent the accumulation of corrosive media on the pallet truck. Try to avoid closed areas, or keep the closed system well ventilated and drained, such as considering the ventilation and heat dissipation of the entire internal combustion pallet truck. The exhaust gas produced by the engine should be discharged from the lower part of the counterweight or the upper part of the counterweight by purification and cooling. For battery forklifts, such as reach pallet truck, ventilation windows can be set to keep the motor cool and ventilated, and there are leakage holes and liquid reservoirs at the bottom of the battery box.

4. Pay attention to avoid crevice corrosion, electrochemical corrosion and stress corrosion cracking. pallet trucks, unavoidable gap structures, such as hood tailor-welded gaps, are sealed with sealant. For the connection of dissimilar metals, metals with similar potential should be selected, or insulating measures should be taken to avoid electrochemical corrosion.

5. When designing parts, consider their uniform corrosion, and select one or several combined anti-corrosion methods. Commonly used protection methods for pallet truck include painting, electroplating, conversion coating, anti-rust oil and grease coating, etc. Different processes have different corrosion resistance.

6. The structure of the parts should facilitate the implementation of protection technology, and process holes should be opened if necessary. For example, for pallet truck, the position of the opening in the fuel tank should be conducive to the spray gun nozzle covering the entire surface for shot blasting. Chemically pretreated workpieces such as top guards should have process holes to prevent liquid accumulation.